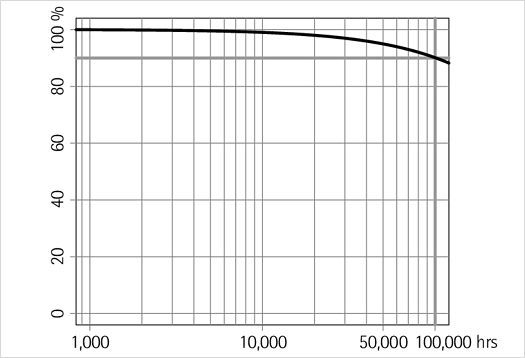

LEDs, as with other light sources, are subject to ageing, causing the luminous flux produced to somewhat decrease. The LED luminous flux maintenance is a statistical parameter that describes how much of the original luminous flux is still emitted after a specific number of operating hours. This decrease is indicated via the L and B values as well as the operating hours in consideration. Both the L value and B value provide no information about the very rare total failure of an LED, the so-called "failure rate".