In principle, every exposure has a damaging effect: colours fade, change their hue and become darker; materials become brittle, dissolve and form cracks.

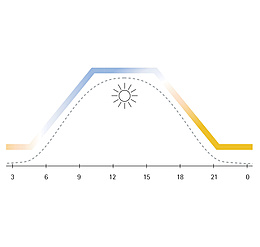

The damage factor (F

dm, rel), also known as the damage index, describes how damaging the radiation of a light source is for colours and the composition of materials. For example, sunlight has both invisible UV radiation and visible short-wave light. For this reason, it is significantly more harmful to many materials than artificial light produced by LEDs.

The damage factor depends on the

spectrum of a light source and the damaging component of the light it contains. It is the quotient of damaging irradiance (W/m²) and illuminance (lx or lm/m²), and is typically expressed in milliwatts per lumen (mW/lm). Values < 0.2 are considered acceptable for illuminating art. While earlier light sources often significantly exceed this value, current high-quality LEDs are below it. Luminaires with a warm white light colour have an advantage here because their spectrum contains no UV radiation and only a low short-wave blue component. The damage factor of these LEDs is well below 0.2.